Pag-unawa sa Walang Putol na Splicing at Hamon ng Pagiging Nakikita ng Bezel

Paglalarawan sa "Walang Putol na Splicing" at ang Kahalagahan Nito sa mga Display Wall

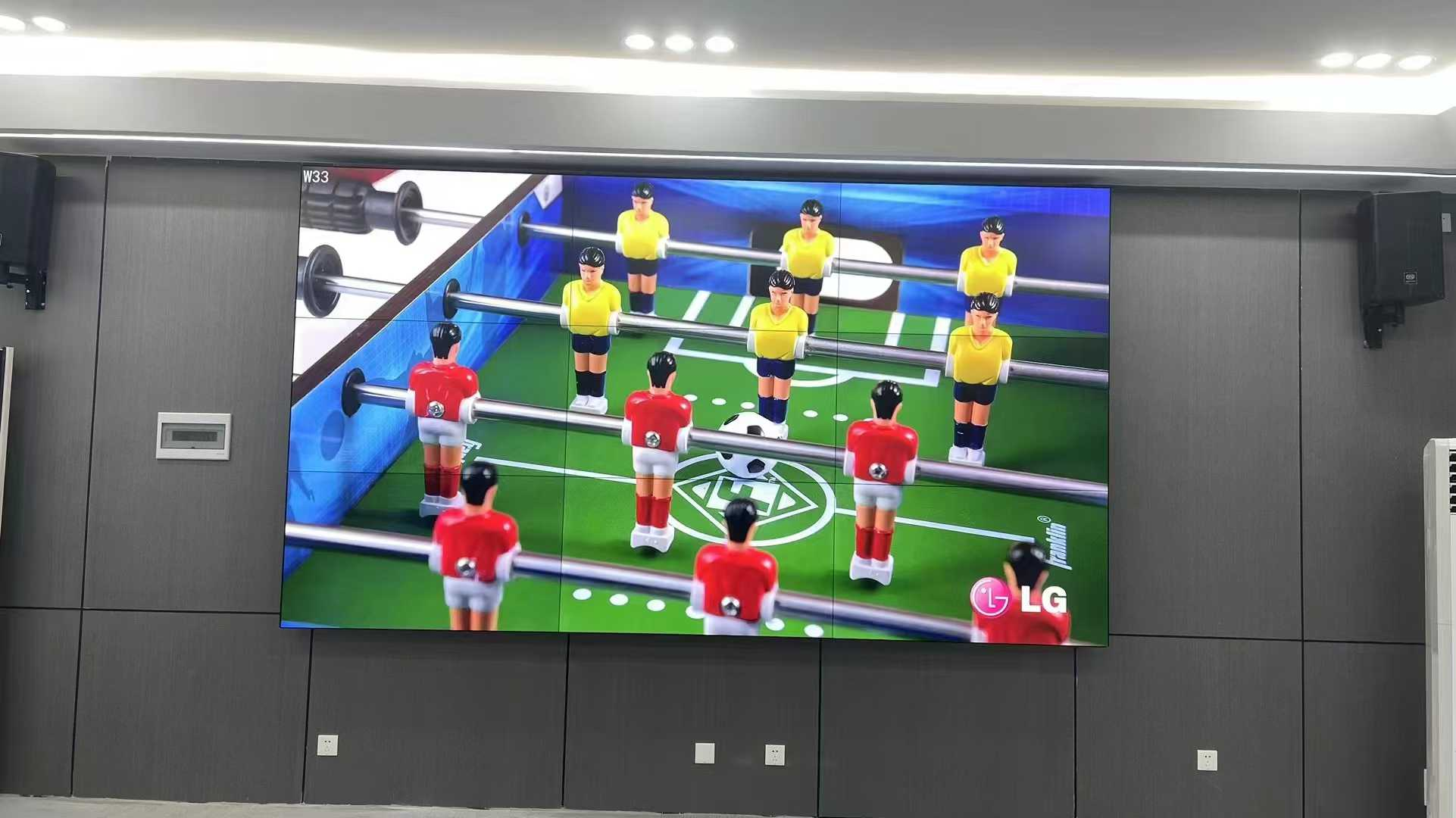

Ang seamless splicing ay nangangahulugan ng pagkakahanay ng ilang LCD panel upang magtrabaho nang buong buo tulad ng isang malaking screen kung saan hindi napapansin kung saan natatapos ang bawat panel. Ang teknolohiyang pampalitik dito ay nagbibigay-daan sa mga video wall na magpakita ng napakalinaw na 4K o kahit 8K na video na parang iisa lang itong larawan. Ang mga lugar na nangangailangan ng tumpak na imahe ay umaasa nang husto sa ganitong uri ng teknolohiya. Isipin ang mga kuwarto ng kontrol sa trapiko ng eroplano kung saan nakasalalay ang mga piloto sa malinaw na imaheng ipinapakita, o sa mga studio ng balita sa telebisyon tuwing live ang broadcast at mahalaga ang bawat pixel. Ayon sa isang kamakailang ulat sa merkado noong 2025, may mahalagang punto ito—sa kasalukuyan, ang mga seamless display ay naging karaniwang kagamitan na sa maraming industriya. Kapag walang puwang sa pagitan ng mga screen, mas mapapabilis at mas mahusay ang desisyon ng mga operator dahil nakikita nila ang lahat nang sabay-sabay nang walang abala.

Ang Tungkulin ng "Pagkakapare-pareho ng Biswal sa Mga Iba't Ibang Yunit ng Display" sa mga Propesyonal na Kapaligiran

Sa mga propesyonal na setting tulad ng mga trading floor at sentro ng operasyong pang-emerhensiya, kahit ang mga maliit na pagkakaiba—tulad ng 0.5% na pagbabago sa ningning—ay maaaring magpabago sa interpretasyon ng datos. Ang mga advanced na LCD splicing system ay nakakamit ng €3% na paglihis sa kulay sa pamamagitan ng pabrikang naika-kalibrang panel at real-time na pagwawasto ng gamma, na nagagarantiya ng pagkakasinkronisar sa antas ng pixel upang suportahan ang tumpak at walang putol na kamalayan sa sitwasyon.

Pangyayari ng Nakikitaang Bezels at ang Pangangailangan para sa "Pagkamit ng Di-nakikitang Seam Mula sa Anumang Anggulo ng Panonood"

Kahit na may mga kamakailang pagpapabuti, ang mga nakikita pa ring bezel ay nagdudulot pa rin ng malaking problema sa mga LCD video wall. Kumuha ng karaniwang 1.8mm bezel bilang halimbawa—ito ay talagang humaharang ng mga 4% sa nakikita natin sa karaniwang 55-pulgadang screen, na lubos na sumisira sa buong epekto ng panoramic. Gayunpaman, may ilang kumpanya nang nakagawa ng mga pag-unlad, tulad ng pagbuo ng micro edge bonding na pumapaliit sa sukat ng bezel hanggang 0.88mm lamang. Subalit, hindi madaling makamit ang perpektong seamless na itsura. Karamihan sa mga pag-install ay nangangailangan pa rin ng karagdagang mga paraan. Ang pag-anggulo ng mga panel sa tiyak na mga anggulo ay malaki ang tulong, at may ilang setup na gumagamit pa ng mga espesyal na takip na salamin na nagbabago ng landas ng liwanag upang itago ang mga nakakaabala nitong puwang sa pagitan ng mga screen mula sa anumang anggulo ng panonood.

Mga Pagbabagong Teknolohikal: Mga Optikal at Elektronikong Teknolohiya para sa Tunay na Seamless

Optikal na Seamless na Pagsasama Gamit ang Mga Panel na Salamin at Prinsipyo ng Refraction upang Bawasan ang Biswal na Puwang

Ang mga layer ng salamin na idinisenyo nang partikular para sa layuning ito ay nagiging mahalaga upang itago ang mga nakakaabala at nakikitang semento sa pagitan ng mga panel. Kapag inilapat ng mga tagagawa ang teknolohiya ng kompensasyon sa distorsyon sa gilid sa kanilang 2.5D curved glass overlays, natatagumpay nilang palabuin ang liwanag nang tama upang ang mga bezel ay maging mas mahirap makita. Ayon sa ilang pagsubok, binabawasan ng pamamarang ito ang mga nakikitang bahagi ng bezel ng humigit-kumulang 72% kumpara sa mga standard display, ayon sa isang pananaliksik na iprinisinta noong DisplayWeek noong nakaraang taon. Bukod dito, ang mga espesyal na nano coating ay tumutulong na ipakalat ang liwanag sa paligid ng bawat gilid ng panel. Dahil dito, ang mga semento ay halos nawawala kahit pa magbago ang ilaw sa paligid ng silid, at nakatutulong rin ito upang ang iba't ibang display ay magmukhang mas pare-pareho kapag inilagay ang mga ito magkaside sa mga instalasyon.

Elektronikong Seamless Splicing na may LED Pixel Compensation at SMD Technology

Gumagamit ang mga SMD LED array ng isang tinatawag na adaptive pixel mapping na nangangahulugang inuunat nito ang mga aktibong lugar ng ilaw mula sa isang panel papunta sa susunod, na nakakatulong upang mapunan ang mga nakakaabala na puwang sa pagitan ng mga bahagi ng kagamitan. Ano ang resulta? Napakahusay din na pagkakapare-pareho ng kulay. Ayon sa mga pag-aaral tungkol sa pagganap ng mga display na ito sa tunay na propesyonal na setting, mayroon itong halos 98.6% na uniformity sa kabuuan ng mga gilid ng panel. Talagang hindi masama. At pagdating sa pagpapanatiling maayos ang takbo ng operasyon, mahusay na ginagawa ng high speed driver ICs ang kanilang trabaho. Pinagsasabay nila ang mga refresh rate nang may halos walang delay—mas mababa sa 0.02 milisegundo—na nangangahulugan ng walang flickering o kakaibang problema sa pagkakaayos kapag ipinapakita ang mga video na may mabilis na aksyon o mga sporting event.

| TEKNOLOHIYA | Sakop ng Bezel | Kwalidad ng kulay | Paggamit sa Galaw |

|---|---|---|---|

| Pagbaluktot ng Liwanag | 92% | δE < 1.5 | € 120Hz |

| Elektronikong Pagdikit | 99% | δE < 0.8 | € 240Hz |

Integrasyon ng Micro-LED at Mas Mga Tuyot na Tendensya na Bawasan ang Pagkakakilanlan sa Seam

Ang pinakabagong teknolohiya ng micro LED ay kayang umabot na sa pixel pitch na mga 0.88mm, na nangangahulugan na ang mga nakakaabala butas sa pagitan ng mga panel ay praktikal nang nawawala para sa mga manonood na nasa mas malapit kaysa sa humigit-kumulang 1.5 metro. Mayroon ding tinatawag na embedded subpixel redundancy na nai-imbak sa mga display na ito. Pangunahing gumagana ito sa pamamagitan ng pag-activate sa mga karagdagang LED tuwing may problema sa signal sa mga gilid ng screen, upang manatiling tuloy-tuloy ang imahe imbes na maghiwa-hiwalay. Ang isang pag-aaral noong nakaraang taon sa Nature ay nagpakita rin ng napakaimpresibong resulta. Natuklasan ng pag-aaral na ang pamamaraang ito ay binabawasan ang mga problema sa butas ng mga panel ng humigit-kumulang 83 porsyento, lalo na kapansin-pansin sa mga curved screen kung saan mas obvious ang mga puwang. Talagang kamangha-manghang teknolohiya, lalo na't isinasaalang-alang kung gaano kahirap ang teknolohiyang ginamit.

Mga Limitasyon at Pagsusuri sa Gastos-Kinabibilangan ng Mga Advanced na Solusyon sa Hardware

Bagaman ang mga advanced na sistema ay nakakamit ng 99.2% na walang putol na pagganap sa mga kontroladong kapaligiran, maaaring bumaba ang pagganap sa tunay na mundo ng 12—18% dahil sa thermal expansion at calibration drift. Ang mga premium na solusyon ay nagkakahalaga ng humigit-kumulang $1,200/m²—apat na beses na higit pa kaysa sa karaniwang LCD walls—ngunit nag-aalok ng 34% na pagbawas sa gastos sa pagpapanatili sa loob ng limang taon (AVIXA 2023), na nagbibigay-bisa sa pamumuhunan para sa mataas na demand na aplikasyon.

Pamamahala sa Bezel at Pagbubuklod ng Gilid: Pagtutugon sa mga Puwang Gamit ang Software at Disenyo

Mga Inobasyon sa Pamamahala ng Bezel ng LCD Splicing Screen upang Bawasan ang Biswal na Pagkagambala

Ang lapad ng bezel ay pininements na hanggang 0.88mm (Display Supply Chain 2024), na malaki ang naitutulong sa pagbawas ng mga patay na lugar. Ang mga modernong disenyo ay sumasaliw ng pixel shifting papaibaba at marunong na image masking upang itago ang metalikong border, habang ang anti-glare coating ay binabawasan ang reflections sa mga madilim na lugar tulad ng broadcast studio, na nagpapahusay sa kabuuang biswal na pagkakaisa.

Paglalapat ng Edge Blending & Seam Correction Algorithms para sa Mga Maganang Transisyon

Kapag hindi magawa ng hardware na alisin ang mga seams, ang mga edge blending algorithm ay naglalapat ng gradwal na transparency masks sa mga overlapping na rehiyon—karaniwang 48 pixels ang lapad—upang mapakinis ang mga transisyon. Ang feathering gradients ay nagtatago sa mga maliit na misalignment na katumbas lamang ng 0.2mm, samantalang ang keystone correction ay nag-aayos ng geometry para sa non-perpendicular na pagtingin. Ang real-time color engines naman ay nagpapanatili ng gamma consistency sa kabuuan ng mga panel, upang mapanatili ang imahe nang may kahusayan.

Pagsusuri sa Kontrobersya: Pagwawasto sa Pamamagitan ng Software vs. Pag-alis ng Seam sa Antas ng Hardware

Kahit ang ilang mga teknisyan na sumusunod pa rin sa lumang paraan ay naniniwala sa mga hardware fix tulad ng mga sobrang manipis na bezel na nasa ilalim ng kalahating milimetro o ang mahalagang fused optical bonding para sa ganap na seamless na display, karamihan ngayon ay gumagamit ng pinagsamang pamamaraan. Ayon sa mga numero noong nakaraang taon tungkol sa Video Wall Integration, humigit-kumulang pitong beses sa sampung setup sa control room ay pinagsasama ang mga narrow bezel panel kasama ang mga software trick na nag-aayos ng kulay at naglulutas ng mga isyu sa pagkaka-align. Ang pagsasamang ito ay nagbibigay-daan sa mga operator na makakuha ng katumbas na resulta nang hindi umaabot sa bulsa para sa mahahalagang solusyon na hardware lahat.

Paggamot sa Video at Pagkakasinkronisa para sa Real-Time na Seamless na Display

Papel ng "video processor para sa multi-screen synchronization" sa pagkaka-align ng timing

Ang mga advanced na video processor ay nagsisiguro ng walang putol na operasyon sa pamamagitan ng pag-synchronize ng frame rate at pagkompensar sa mga delay sa transmisyon sa iba't ibang display. Na suportahan ang mga input tulad ng HDMI at SDI, ang mga processor na ito ay dinesisenyong umangkop sa mga pagbabago ng resolusyon, panatilihin ang tumpak na pagkaka-align ng pixel kahit sa panahon ng mabilis na paglipat ng eksena—ito ay mahalaga sa mga kapaligiran na sensitibo sa oras tulad ng monitoring.

Paano pinapagana ng "hdmi seamless matrix" ang real-time na "seamless switching" nang walang latency

Ang mga HDMI seamless matrix ay nagpipigil sa blackout tuwing nagbabago ng source sa pamamagitan ng pre-buffering ng signal at patuloy na pagpapanatili ng komunikasyon (handshake) sa pagitan ng mga source at display. Dahil sa oras ng paglipat na nasa ilalim ng 50ms—na hindi napapansin ng mata ng tao—ang teknolohiyang ito ay napakahalaga sa broadcast at seguridad kung saan kritikal ang walang putol na visual feed.

Pagsisiguro ng pagkakaisa ng frame sa lahat ng display gamit ang genlock at lip-sync na teknolohiya

Ang pag-synchronize ng genlock ay nag-aayos ng lahat ng display sa isang solong pinagmulan ng oras, na pinapaliit ang pagkakaiba-iba ng timing sa ilalim ng 1μs. Ang mga pampalakas na protocol para sa lip-sync ay nagpapanatili ng pagkakaayos ng audio at video sa mga multi-panel na setup, na lubhang mahalaga para sa malalim o sinematikong nilalaman. Ang adaptive phase-locked loops ay awtomatikong binabawasan ang signal lag dulot ng pagkakaiba-iba sa haba ng kable.

Estratehiya: Pagpili ng mga processor na sumusuporta sa 4K@60Hz sa buong mga naispis na array

Para sa pinakamahusay na pagganap, pumili ng mga video processor na kayang humawak ng resolusyon na 4K sa 60Hz bilang minimum. Sinisiguro nito ang sapat na bandwidth para sa HDR content at pinapaliit ang mga artifact sa galaw. I-verify ang kakayahang magtrabaho kasama ng mga EDID management system, na awtomatikong nag-o-optimize ng mga parameter ng signal para sa mga panel na magkakaiba ang henerasyon sa loob ng iisang array.

Pag-install, Pagtutune, at Pagpapanatili para sa Matagalang Walang-hiwalay na Pagganap

Pinakamahuhusay na gawi sa "pag-install at pagtutune ng mga naispis na screen"

Mahalaga ang eksaktong pag-install para sa matagalang walang putol na operasyon. Ayon sa mga pag-aaral sa pang-industriyang pagpapanatili, ang mga kasangkapan na pinapatnubayan ng laser ay nagbaba ng agwat sa pagitan ng mga panel sa ilalim ng 0.88mm—60% mas maliit kumpara sa tradisyonal na pamamaraan—na nagrereport ng mga field engineer na gumagamit ng istrukturadong protokol sa pag-install ng 40% mas mabilis na commissioning sa pamamagitan ng pagtugon sa mekanikal na pagkaka-align bago ang elektrikal na pagkaka-sync.

Pagkamit ng katumpakan sa pamamagitan ng "alignment & mounting" gamit ang mga kasangkapang pinapatnubayan ng laser

Gumagamit ang modernong mga sistema ng infrared positioning na may 0.1mm na repeatability, na epektibong nag-aalis ng mga anino dulot ng bezel. Kapag isinama sa matitibay na mounting frame na nakakalaban sa pagde-deform dahil sa thermal stress, ang husay na ito ay nagpapanatili ng uniformidad ng kulay sa loob ng ΔE<2 sa magkakalapit na panel.

Pagsasaklaw para sa "hindi pare-parehong liwanag o pagsasa-kalibre ng kulay" gamit ang spectrophotometer

Ginagamit ang spectrophotometer sa kalibrasyon pagkatapos ng pag-install upang i-match ang antas ng luminansya sa loob ng 50-nit na saklaw sa lahat ng panel. Ang mga awtomatikong algorithm ng kompensasyon ay nalulutas ang 92% ng mga chromatic aberration habang nasa paunang tuning—mula sa dating 75% gamit ang manu-manong kalibrasyon (Display Metrology Report 2023)—na nagtitiyak ng pare-parehong kalidad ng imahe.

Multi-screen linkage gamit ang propesyonal na splicing screen controllers at software

Ang mga sentralisadong controller ay gumagamit ng genlock protocol upang isinsisnchronize ang refresh rate na may sub-1ms latency, mahalaga para sa live monitoring applications. Ang mga edge-blending processor ay pinapalawig ang imahe ng 2—3 pixels lampas sa pisikal na gilid, tinatakpan ang natitirang visibility ng bezel at pinalalakas ang visual continuity.

Pagsusuri at pagsusuri sa epekto ng display sa live na kapaligiran ng control room

Ang huling pag-beripika ay kasama ang 72-oras na stress test sa ilalim ng operasyonal na antas ng kaliwanagan, upang matukoy ang mga isyu tulad ng thermal expansion gaps o backlight drift bago ma-ihanda ang sistema.

Pangangalaga, pag-upgrade, at modular na disenyo para sa mga video wall system na handa para sa hinaharap

Ang modular na panel na may tool-less disassembly ay nagpapahintulot ng target na pagpapalit nang hindi kinakailangang buwagin ang buong pader, na bawas hanggang 80% ang downtime. Ang nakatakda na recalibration tuwing 6—12 buwan ay sumisiguro laban sa di-pantay na pagtanda ng LED, pinapanatili ang katumpakan ng kulay at pinalalawak ang haba ng buhay ng sistema.

Seksyon ng FAQ

Ano ang seamless splicing sa mga display wall?

Ang seamless splicing ay tumutukoy sa teknolohiya ng pagkaka-align ng maramihang LCD panel upang gumana bilang isang malaking screen, nang walang visible gaps sa pagitan nila.

Bakit pa rin problema ang visible bezels sa mga LCD video wall?

Ang visible bezels ay humahadlang sa bahagi ng visual na nilalaman ng display, nag-iinterfere sa layuning panoramic effect at seamless viewing experience.

Paano miniminimize ng glass panel ang visual gaps?

Ang mga layer ng salamin na dinisenyo gamit ang tiyak na prinsipyo ng refraction ay binabale ang liwanag upang itago ang mga seams sa pagitan ng mga panel, kaya miniminimize ang visual gaps.

Ano ang papel ng HDMI seamless matrices sa mga display wall?

Ang HDMI seamless matrices ay nagsisiguro ng walang patlang na visual feeds sa pamamagitan ng pagpigil sa blackouts habang nagbabago ng source at patuloy na pinapanatili ang komunikasyon sa pagitan ng mga source at display.

Paano nakamit ang matagalang seamless performance sa video walls?

Sa pamamagitan ng tumpak na pag-install, laser-guided alignment, regular na calibration, at paggamit ng modular designs na nagbibigay-daan sa madaling maintenance.

Talaan ng mga Nilalaman

-

Pag-unawa sa Walang Putol na Splicing at Hamon ng Pagiging Nakikita ng Bezel

- Paglalarawan sa "Walang Putol na Splicing" at ang Kahalagahan Nito sa mga Display Wall

- Ang Tungkulin ng "Pagkakapare-pareho ng Biswal sa Mga Iba't Ibang Yunit ng Display" sa mga Propesyonal na Kapaligiran

- Pangyayari ng Nakikitaang Bezels at ang Pangangailangan para sa "Pagkamit ng Di-nakikitang Seam Mula sa Anumang Anggulo ng Panonood"

-

Mga Pagbabagong Teknolohikal: Mga Optikal at Elektronikong Teknolohiya para sa Tunay na Seamless

- Optikal na Seamless na Pagsasama Gamit ang Mga Panel na Salamin at Prinsipyo ng Refraction upang Bawasan ang Biswal na Puwang

- Elektronikong Seamless Splicing na may LED Pixel Compensation at SMD Technology

- Integrasyon ng Micro-LED at Mas Mga Tuyot na Tendensya na Bawasan ang Pagkakakilanlan sa Seam

- Mga Limitasyon at Pagsusuri sa Gastos-Kinabibilangan ng Mga Advanced na Solusyon sa Hardware

- Pamamahala sa Bezel at Pagbubuklod ng Gilid: Pagtutugon sa mga Puwang Gamit ang Software at Disenyo

-

Paggamot sa Video at Pagkakasinkronisa para sa Real-Time na Seamless na Display

- Papel ng "video processor para sa multi-screen synchronization" sa pagkaka-align ng timing

- Paano pinapagana ng "hdmi seamless matrix" ang real-time na "seamless switching" nang walang latency

- Pagsisiguro ng pagkakaisa ng frame sa lahat ng display gamit ang genlock at lip-sync na teknolohiya

- Estratehiya: Pagpili ng mga processor na sumusuporta sa 4K@60Hz sa buong mga naispis na array

-

Pag-install, Pagtutune, at Pagpapanatili para sa Matagalang Walang-hiwalay na Pagganap

- Pinakamahuhusay na gawi sa "pag-install at pagtutune ng mga naispis na screen"

- Pagkamit ng katumpakan sa pamamagitan ng "alignment & mounting" gamit ang mga kasangkapang pinapatnubayan ng laser

- Pagsasaklaw para sa "hindi pare-parehong liwanag o pagsasa-kalibre ng kulay" gamit ang spectrophotometer

- Multi-screen linkage gamit ang propesyonal na splicing screen controllers at software

- Pagsusuri at pagsusuri sa epekto ng display sa live na kapaligiran ng control room

- Pangangalaga, pag-upgrade, at modular na disenyo para sa mga video wall system na handa para sa hinaharap

- Seksyon ng FAQ